AI, Robotics, and IoT Drive Innovation in the Mining Automation Market

The global mining automation market is on the brink of a major transformation, fueled by the rapid deployment of smart mining technologies. As demand for minerals like lithium, copper, cobalt, and rare earth elements rises sharply—driven by the clean energy transition and the electrification of transportation—the mining industry is under pressure to become more efficient, productive, and sustainable. Automation is no longer an optional upgrade; it is fast becoming the foundation of the next-generation mining operation.

The Evolution of Automation in Mining

Traditionally, mining has been a labor-intensive and hazard-prone sector. With operations often located in remote areas, mining activities require significant human effort, exposing workers to extreme temperatures, dust, vibration, and the constant risk of injury. Over the last decade, mining companies began integrating automated systems to remove workers from dangerous environments and improve operational efficiency. What started with basic mechanization has evolved into sophisticated automation that leverages robotics, artificial intelligence (AI), and real-time analytics.

Mining automation today encompasses a wide range of technologies—from autonomous trucks and drill rigs to remotely operated control centers. These innovations are not only reducing the need for human intervention but also enabling continuous, round-the-clock operations that are optimized for energy efficiency and resource utilization.

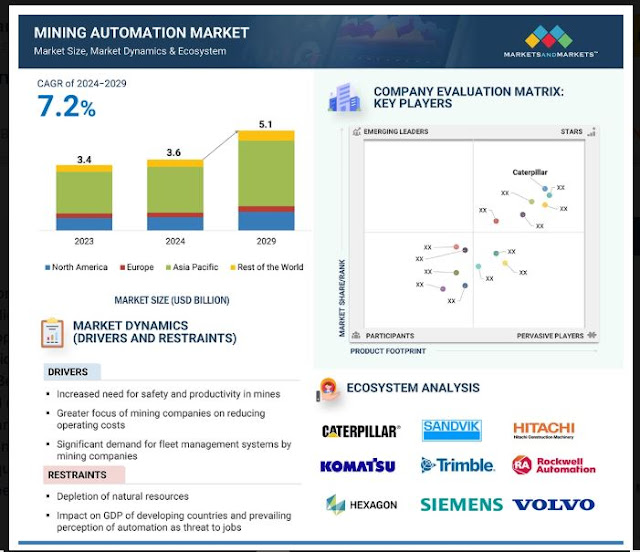

The global mining automation industry size is expected to grow from USD 3.6 billion in 2024 to USD 5.1 billion by 2029, at a CAGR of 7.2% from 2024 to 2029. The global mining industry is experiencing a significant shift towards digital transformation, emphasizing enhancing worker safety and boosting productivity. This trend is propelling the growth of the mining automation industry . The emergence of connected mines and a growing imperative to reduce operational costs further expand the market. These combined factors underscore the dynamic evolution and increasing adoption of automation technologies within the mining sector.

Smart Mining Technologies Reshaping the Industry

Smart mining technologies are driving the shift toward highly intelligent, connected, and autonomous operations. At the core of this transformation is the convergence of digital tools such as AI, machine learning, the Internet of Things (IoT), cloud computing, and advanced sensor networks. These technologies provide mining operators with unprecedented visibility and control over every aspect of their value chain—from exploration and extraction to logistics and processing.

Autonomous haulage systems (AHS), for example, allow large trucks to navigate complex terrain without drivers, reducing labor costs while improving fuel efficiency and safety. Similarly, automated drilling systems can execute precision tasks with greater speed and accuracy, minimizing human error and reducing waste. Remote operations centers, often located in urban areas far from mine sites, now oversee entire fleets and monitor production, environmental conditions, and equipment health in real time.

Drones and unmanned aerial vehicles (UAVs) are increasingly being used for aerial mapping, volumetric analysis, and environmental monitoring. Their integration with data platforms enables companies to make faster, more informed decisions. These tools, combined with predictive maintenance powered by AI, are helping to reduce unplanned downtime and extend the life of critical assets.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=257609431

A Response to Global Challenges and ESG Pressures

One of the major catalysts for automation in the mining sector is the global push for sustainability and adherence to environmental, social, and governance (ESG) principles. Automation enables companies to reduce their carbon footprint through more efficient fuel usage and optimized logistics. Smart energy management systems can monitor power consumption and emissions, allowing firms to align with regulatory standards and investor expectations.

Additionally, mining automation plays a key role in community safety and social responsibility. By minimizing the number of workers on-site, companies reduce the risk of occupational hazards and promote a safer, more controlled environment. Remote operations also open up new job opportunities in data analysis, equipment maintenance, and digital system management, shifting the nature of mining employment from physical to digital skill sets.

Regional Trends and Growth Potential

The mining automation market is gaining strong traction across various geographies. In Australia, major players like Rio Tinto and BHP have already adopted fully autonomous mine operations in the Pilbara region. Their success has set a global benchmark for innovation and efficiency. North America follows closely, with increasing investment in AI-driven analytics and robotic solutions across both surface and underground mining.

Asia-Pacific, home to some of the world’s largest mineral reserves, is expected to witness the fastest market growth, particularly in China and India. These countries are heavily investing in digital mining infrastructure to enhance production and reduce reliance on manual labor. In Latin America and Africa, where logistical and infrastructural challenges are more pronounced, automation is seen as a way to leapfrog traditional constraints and operate at global standards.

Challenges and Industry Roadblocks

Despite its many advantages, mining automation comes with its share of challenges. One of the most prominent is the high capital expenditure required to implement automated systems. Small and mid-sized operators often find it difficult to justify these upfront costs, particularly when commodity prices are volatile. Another key barrier is the complexity of integrating new technologies with legacy systems, many of which were not designed to support modern digital platforms.

Cybersecurity also emerges as a growing concern as operations become more connected and data-driven. With automation relying heavily on software and cloud-based systems, mining companies must invest in robust cybersecurity frameworks to protect against data breaches and operational disruptions.

Equally important is the need for workforce transition. As traditional jobs are phased out, there is a growing need to retrain workers for roles in data science, remote equipment management, and systems engineering. Ensuring inclusive growth and equitable access to these new opportunities will be essential for long-term industry stability.

The Future of Mining Automation: A Digital, Connected Ecosystem

Looking ahead, the future of the mining automation market is one of intelligent ecosystems where machines, data, and humans work in harmony. The integration of 5G connectivity will further enhance communication between autonomous systems, while cloud platforms will enable global operations to be managed from centralized hubs. In time, technologies like edge computing and augmented reality (AR) could become mainstream tools in mine management and maintenance.

The key players in this industry include Caterpillar (US), Komatsu Ltd. (Japan), Sandvik AB (Sweden), Epiroc AB (Sweden), Hitachi Construction Machinery Co., Ltd. (Japan), and others.

About MarketsandMarkets™

MarketsandMarkets™ has been recognized as one of America's Best Management Consulting Firms by Forbes, as per their recent report.

MarketsandMarkets™ is a blue ocean alternative in growth consult611ing and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. With the widest lens on emerging technologies, we are proficient in co-creating supernormal growth for clients across the globe.

Today, 80% of Fortune 2000 companies rely on MarketsandMarkets, and 90 of the top 100 companies in each sector trust us to accelerate their revenue growth. With a global clientele of over 13,000 organizations, we help businesses thrive in a disruptive ecosystem.

The B2B economy is witnessing the emergence of $25 trillion in new revenue streams that are replacing existing ones within this decade. We work with clients on growth programs, helping them monetize this $25 trillion opportunity through our service lines – TAM Expansion, Go-to-Market (GTM) Strategy to Execution, Market Share Gain, Account Enablement, and Thought Leadership Marketing.

Built on the 'GIVE Growth' principle, we collaborate with several Forbes Global 2000 B2B companies to keep them future-ready. Our insights and strategies are powered by industry experts, cutting-edge AI, and our Market Intelligence Cloud, KnowledgeStore™, which integrates research and provides ecosystem-wide visibility into revenue shifts.

To find out more, visit www.MarketsandMarkets™.com or follow us on Twitter , LinkedIn and Facebook .

Contact:

Mr. Rohan Salgarkar

MarketsandMarkets™ INC.

1615 South Congress Ave.

Suite 103, Delray Beach, FL 33445

USA: +1-888-600-6441

,%20General%20Circuitry%20(SPXO,VCXO%20(TCVCXO,%20OCVCXO),%20TCXO,%20OCXO%20(DOCXO,%20EMXO),%20FCXO),%20Crystal%20Cut%20(AT-cut,%20BT-cut,%20SC-cut)%20(2).jpg)

.jpg)

,%20Technology%20(Machine%20Learning,%20GenAI),%20Function%20(Training,%20Infere.jpg)

,%20Network%20Technology%20(Wired%20and%20Wireless),%20Vertical%20(Commercial%20IoT%20and%20Industrial%20IoT)%20(3).jpg)

No comments: